Hydrostatic Testing

- 28″ x 28″ x 36″ Chamber

- 0-3,600 PSI Air/Hydro Pump

- 0-45,000 PSI Air/Hydro Pump

- Additel Pressure Transducers w/Standalone Data Logging

- NI cDAQ | Strain, LVDT, Transducer, Thermocouple

- High Speed Camera

High Speed Camera

- FreeFly WAVE

- 2TB onboard SSD

- 4K – 420 fps | 2K – 1440 fps

- Remote trigger

- Ballistic resistant tripod mount case

- Macro lens

- 2x 10″ x 15″ LED panel lights

KEYENCE Laser Profiler

- 2D and 3D Laser Profile Scanning

- 3200 Point Beam

- 8″ – 12″ Beam Span

- 0.0025″ – 0.00375″ Point Resolution

- 0.002″ Deflection Accuracy

- Z-Axis Accuracy depends on dimensions and encoder jig

NI cDAQ Data Acquisition

National Instruments cDAQ 9189

Inputs:

- Voltage +/- 10 VDC

- Current 0-20mA

- Strain Resistor Bridge

Output Controls:

- Relay output 0-60 VDC

- Voltage 0-10 VDC

Sensor Hardware:

- 1-3 Axis Strain Gauges

- Analog LVDTs | 2″ – 6″ deflection

- Pressure Transducers 500 – 50,000 PSI

- Load Cells 2,000 – 30,000 lbf

Thermal Control System

- WATLOW 4 Channel PID temperature controller

- 220VAC 100A (22kW) Total Power*

- Up to 6x 220VAC x 4A (880W) elements per channel

- 220VAC x 25A (5.5kW) max single element per channel

*Power limited at SEI facility to 30A (6.6kW) | Unit available for rent

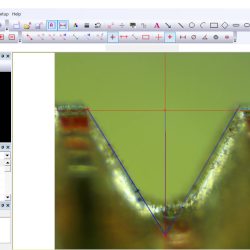

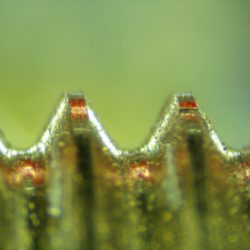

Microscopic Inspection

-

-

- Digital Microscope

- 2″ x 2″ Travel XY Table with 0.00005″ Accuracy DRO

-